Hey guys, you have all been great help with ideas and know how of tricks and skills to get this thing dialed in! I'm still having issues with getting this thing to idle. Recap: I've got a d0ve A 429 block bored .030 over, sealed power 2366 forged flat tops with one valve relief, stock rods, stock 429 crank, .015 in the hole, comp cams 34-602-5 cam(big mutha thumper), edelbrock torker 2 intake, Holley 700 double pumper, Mallory dual point (eliminated points and installed pertronix 2). Initial timing I've had it set from 14°-18°, with total being 34°.Best results down around 14° initial but had a really rough shake to the engine at 700 rpm. Extremely doggy off idle until it got up around 3k rpm. It idled but had a pretty aggressive shake to it, guys were saying to crack the secondaries open a bit to help get air, so I did. That helped a little, but still had the shake (although not as bad) Guys said to drill 1/8" holes in primary throttle blades, so I did, and now I can't get it to idle less than 1200 rpm. I can get it to get down around the 1000 rpm range, but won't stay running. When you give it throttle it is it pretty responsive, but then stays up pretty high in the rpm, takes a bit for it to want to come back down to an idle, and when it does, it falls off and dies if you don't feather the throttle. The carb has a fresh kit in it, but I'm concerned on wether or not this carb is what I should be running? Can I make this setup work, or should I go a different route? This is in a 1970 torino cobra, 4 speed trans, 4.30 gear rear end. Intended use is strong street car, mostly cruise ins and car show type stuff, but want that ratty muscle car sound. Any help is greatly appreciated, as always. I'm at around 3,000 ft above sea level. The cam was purchased by the previous owner, and looked like it might be the sound i was after, but wonder if it might be part of my problem? The intake is for one because of the height for the shaker, and two being the rpm range of the cam. I would really like to make this work for this year, and if need be go a different direction this winter. Is it possible? Any suggestions? It kind of feels like I was going in the right direction, but now took two huge steps back!

Dads70cobra

At a loss with these idling issues!

2 reading

Dads70cobra

Discussion starter

23 posts

·

Joined 2016

- Add to quote Only show this user

Hey guys, you have all been great help with ideas and know how of tricks and skills to get this thing dialed in! I'm still having issues with getting this thing to idle. Recap: I've got a d0ve A 429 block bored .030 over, sealed power 2366 forged flat tops with one valve relief, stock rods, stock 429 crank, .015 in the hole, comp cams 34-602-5 cam(big mutha thumper), edelbrock torker 2 intake, Holley 700 double pumper, Mallory dual point (eliminated points and installed pertronix 2). Initial timing I've had it set from 14°-18°, with total being 34°.Best results down around 14° initial but had a really rough shake to the engine at 700 rpm. Extremely doggy off idle until it got up around 3k rpm. It idled but had a pretty aggressive shake to it, guys were saying to crack the secondaries open a bit to help get air, so I did. That helped a little, but still had the shake (although not as bad) Guys said to drill 1/8" holes in primary throttle blades, so I did, and now I can't get it to idle less than 1200 rpm. I can get it to get down around the 1000 rpm range, but won't stay running. When you give it throttle it is it pretty responsive, but then stays up pretty high in the rpm, takes a bit for it to want to come back down to an idle, and when it does, it falls off and dies if you don't feather the throttle. The carb has a fresh kit in it, but I'm concerned on wether or not this carb is what I should be running? Can I make this setup work, or should I go a different route? This is in a 1970 torino cobra, 4 speed trans, 4.30 gear rear end. Intended use is strong street car, mostly cruise ins and car show type stuff, but want that ratty muscle car sound. Any help is greatly appreciated, as always. I'm at around 3,000 ft above sea level. The cam was purchased by the previous owner, and looked like it might be the sound i was after, but wonder if it might be part of my problem? The intake is for one because of the height for the shaker, and two being the rpm range of the cam. I would really like to make this work for this year, and if need be go a different direction this winter. Is it possible? Any suggestions? It kind of feels like I was going in the right direction, but now took two huge steps back!

Dads70cobra

Discussion starter

23 posts

·

Joined 2016

Let me add, it has d0ve c heads, with mild port job, enlarged valves 2.19 intake 1.72 exhaust. 75cc chambers

372 posts

·

Joined 2009

I'm not an expert by any means, but it sounds like you might still have the transfer slot uncovered too much (maybe the rear?). If you have drilled the front throttle blades, where did you drill them? And did you put the rear back where it was after you drilled them? I am thinking you don't need both the front drilled and the rear opened up. Also what kind of manifold vacuum do you have? And waht size power valve? There is lots of advice on what size it should be based in manifold vacuum but the key is not to have it open during idle.

I have basically the same engine and cam. I have a 1970 429 with Eddy heads (but I did have the D0VE-C heads before) and the Big Mutha Thumper cam. My car needs a lot more air to idle but I was able to get by with just opening the secondaries a bit. I have a 750 on it now but was running a 770. Both of those were able to be tuned fairly easy. Maybe the bigger carb helps but I have a strong low end and no stumble off idle. You said you have a 700cfm? I didn't know there was such a thing.

I recurved my Duraspark distributor based on advice from Scott the Mad Porter. Timing is very important but it sounds like you have that set. The other big difference is I have a Edelbrock Performer intake which is a dual plane. The Torker II might be hurting a little being a single plane but I am not sure. Also I live in KY which is no where near 3000 feet so the thinner air is not helping.

I have basically the same engine and cam. I have a 1970 429 with Eddy heads (but I did have the D0VE-C heads before) and the Big Mutha Thumper cam. My car needs a lot more air to idle but I was able to get by with just opening the secondaries a bit. I have a 750 on it now but was running a 770. Both of those were able to be tuned fairly easy. Maybe the bigger carb helps but I have a strong low end and no stumble off idle. You said you have a 700cfm? I didn't know there was such a thing.

I recurved my Duraspark distributor based on advice from Scott the Mad Porter. Timing is very important but it sounds like you have that set. The other big difference is I have a Edelbrock Performer intake which is a dual plane. The Torker II might be hurting a little being a single plane but I am not sure. Also I live in KY which is no where near 3000 feet so the thinner air is not helping.

5,482 posts

·

Joined 2006

Sounds like you're running the vac advance off the ported vac. Try running it off full manifold vacuum if you're not already. Power valve would also be something to look at. Probably need a 3.5 in there.Hey guys, you have all been great help with ideas and know how of tricks and skills to get this thing dialed in! I'm still having issues with getting this thing to idle. Recap: I've got a d0ve A 429 block bored .030 over, sealed power 2366 forged flat tops with one valve relief, stock rods, stock 429 crank, .015 in the hole, comp cams 34-602-5 cam(big mutha thumper), edelbrock torker 2 intake, Holley 700 double pumper, Mallory dual point (eliminated points and installed pertronix 2). Initial timing I've had it set from 14°-18°, with total being 34°.Best results down around 14° initial but had a really rough shake to the engine at 700 rpm. Extremely doggy off idle until it got up around 3k rpm. It idled but had a pretty aggressive shake to it, guys were saying to crack the secondaries open a bit to help get air, so I did. That helped a little, but still had the shake (although not as bad) Guys said to drill 1/8" holes in primary throttle blades, so I did, and now I can't get it to idle less than 1200 rpm. I can get it to get down around the 1000 rpm range, but won't stay running. When you give it throttle it is it pretty responsive, but then stays up pretty high in the rpm, takes a bit for it to want to come back down to an idle, and when it does, it falls off and dies if you don't feather the throttle. The carb has a fresh kit in it, but I'm concerned on wether or not this carb is what I should be running? Can I make this setup work, or should I go a different route? This is in a 1970 torino cobra, 4 speed trans, 4.30 gear rear end. Intended use is strong street car, mostly cruise ins and car show type stuff, but want that ratty muscle car sound. Any help is greatly appreciated, as always. I'm at around 3,000 ft above sea level. The cam was purchased by the previous owner, and looked like it might be the sound i was after, but wonder if it might be part of my problem? The intake is for one because of the height for the shaker, and two being the rpm range of the cam. I would really like to make this work for this year, and if need be go a different direction this winter. Is it possible? Any suggestions? It kind of feels like I was going in the right direction, but now took two huge steps back!

Aside from that, that's a whole lot of cam without much in the way of lobe separation. They're pretty much designed to give you a rough idle with low vacuum, and low power below 3000 is about what you should expect.

.

Dads70cobra

Discussion starter

23 posts

·

Joined 2016

Okay, some great feed back! The carb list number is a 4778-2, which, everywhere i look comes back as a 700 cfm. It was a brand new carb (still in factory packaging) when I got it from the last owner. It is an older carb, so i thought maybe some gaskets might have been bad, along with accelerator pumps, and wanted to put the correct size power valve in it which I figured to be 3.5. So I did a kit and power valve. I had 5-6 inches of vacuum, but now can't get it to idle long enough to see vacuum readings. I drilled the holes on the front half of the blades. (1) 1/8" hole in each blade. I have the vacuum advance unhooked and plugged at the moment, trying to get initial timing set.

Dads70cobra

Discussion starter

23 posts

·

Joined 2016

Tara-fied...... yours is exactly what I'm trying to achieve with this one! I've never had this much trouble getting one to idle. Your engine seems to have no "shake" at all, compared to what mine is doing. It shakes the entire car at an idle, but is smooth as can be 1,000rpm on up. It's is balanced, and I can't find any vacuum leaks, because that is what it kind of acts like! What mufflers are you running?

372 posts

·

Joined 2009

I went from a mild cam to this one and it took some fiddling with the carb to get it to idle. It does not have any shake. I have a C6 with a 2400 stall speed (which may be too low) but It feels strong and no bog or hesitation. Has great throttle response. I have Magnaflow mufflers. They are for an AAR Cuda because I have the side exit setup.

721 posts

·

Joined 2009

The "health" of the engine is really the key before any carb tuning is attempted. Have you done a compression test? Was the camshaft "degreed" when installed? What is the vacuum reading @ idle(800-1000 rpm)? More often than not, an ignition issue can the real culprit but the carburetor usually gets the blame. Make absolutely sure the ignition is up to par before making any major(jets, power valves and/or drilling anything) carb changes.

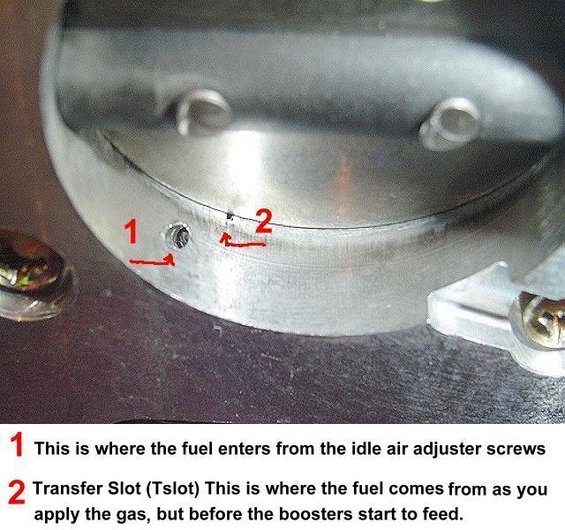

With the throttle blades drilled, you are gaining rpm but also leaning the idle mixture. Before installing carburetor, make sure transfer slots aren't uncovered too much, they should look something like this:

![Image]()

Using a vacuum gauge, set the idle mixture screws to see highest vacuum reading, then add about 1/8-1/4 turn out on the idle mixture screws(doing this makes a real difference when dealing with longer duration camshafts). Try doing this adjustment with engine up to operating temp and trans in DRIVE with someone on the brakes or at least with parking brake applied and the wheels chocked. Adjusting the IMS(idle mixture screws) with the trans in P or N does not take into account the added engine load like when the trans is in DRIVE, more load usually requires richer fuel mixture to have a relatively stable idle. A wideband will help with carb tuning, gives you the ability to see where in the rpm band to focus your attention in carb tuning. There could be other things to try, like smaller idle air bleeds and/or larger idle feed restrictors to allow enhanced low rpm drivability, but without a wideband these are more or less a trial and error endeavor. I have linked this site before, but great carb knowledge found here:

racingfuelsystems.myfunforum.org - Index page

Hope this is helpful.

With the throttle blades drilled, you are gaining rpm but also leaning the idle mixture. Before installing carburetor, make sure transfer slots aren't uncovered too much, they should look something like this:

Using a vacuum gauge, set the idle mixture screws to see highest vacuum reading, then add about 1/8-1/4 turn out on the idle mixture screws(doing this makes a real difference when dealing with longer duration camshafts). Try doing this adjustment with engine up to operating temp and trans in DRIVE with someone on the brakes or at least with parking brake applied and the wheels chocked. Adjusting the IMS(idle mixture screws) with the trans in P or N does not take into account the added engine load like when the trans is in DRIVE, more load usually requires richer fuel mixture to have a relatively stable idle. A wideband will help with carb tuning, gives you the ability to see where in the rpm band to focus your attention in carb tuning. There could be other things to try, like smaller idle air bleeds and/or larger idle feed restrictors to allow enhanced low rpm drivability, but without a wideband these are more or less a trial and error endeavor. I have linked this site before, but great carb knowledge found here:

racingfuelsystems.myfunforum.org - Index page

Hope this is helpful.

Dads70cobra

Discussion starter

23 posts

·

Joined 2016

Thank you! Ill check the link. It is a four speed manual trans.

721 posts

·

Joined 2009

Should have read your posts more carefully before my reply, my apologies. Hope the site and it's members give you the needed info, Great folks there. Good luck.

Dads70cobra

Discussion starter

23 posts

·

Joined 2016

No worries! Any help and info, is greatly appreciated!

3,946 posts

·

Joined 2007

sounds like a vac leak

how far out are the idle screws? set them at 2 out to start

set timing @ 38 total ,and check it at 3000 rpm

whats the plug gap?

what plug?

how far out are the idle screws? set them at 2 out to start

set timing @ 38 total ,and check it at 3000 rpm

whats the plug gap?

what plug?

Dads70cobra

Discussion starter

23 posts

·

Joined 2016

Idle screws are out about 1.5 turns. Plugs are the motorcraft copper core .035 gap.

Dads70cobra

Discussion starter

23 posts

·

Joined 2016

I second the vacuum leak thought, but man, I've checked everything 8 times, and have everything blocked off.

5,482 posts

·

Joined 2006

This is the problem with running a low vacuum cam in a street car. Not enough vacuum at idle to maintain sufficient timing advance, even if you do have the vac adv hooked up to manifold.

You might want to try locking out the distributor. It'll be less than ideal under part throttle cruise conditions, but not horrible, and it'll give you enough timing at low rpm to support a more stable idle. You'll just have to be cautious about WOT at low rpms.

.

You might want to try locking out the distributor. It'll be less than ideal under part throttle cruise conditions, but not horrible, and it'll give you enough timing at low rpm to support a more stable idle. You'll just have to be cautious about WOT at low rpms.

.

Dads70cobra

Discussion starter

23 posts

·

Joined 2016

I do understand that this is the problem with the low vacuum crankshaft that I have, now. Shame on myself for not looking into this camshaft more, before I installed it. At this point, I'm just trying to get through this season, and look into a more streetable camshaft this next winter. I'm in question with wheat i have going on, because guess are using this setup without my issues, as noted above. I do appreciate all feedback, as I want to get this corrected. Thank you!

26 posts

·

Joined 2021

Can you put a dedicated vacuum can in the system to maintain a steady vac at idle?

504 posts

·

Joined 2006

Do you guys prefer to run "full manifold vacuum" (full vacuum timing advance) at idle on your street builds?

I run ported vacuum (no vacuum to distributor) at idle. Timing starts to advance when throttle plates open a little. With full manifold vacuum my idle is too high and could not lower enough with just the idle screw (although I would explore this further if it is recommended to run full manifold vacuum for reasons I don't understand).

UPDATE: I wanted to post this link - it has a good explanation of ported vs manifold vacuum, so that anyone else coming along later that reads this may find it useful. Basically, always use manifold vacuum when possible since the idle mixture is generally lean on most carbs (and due to overlap/cylinder dilution) compared to high engine loads and acceleration, and lean mixtures need more spark advance. (one exception could be having a cam installed that results in fluctuating idle vacuum).

http://chevellestuff.net/tech/articles/vacuum/port_or_manifold.htm

I run ported vacuum (no vacuum to distributor) at idle. Timing starts to advance when throttle plates open a little. With full manifold vacuum my idle is too high and could not lower enough with just the idle screw (although I would explore this further if it is recommended to run full manifold vacuum for reasons I don't understand).

UPDATE: I wanted to post this link - it has a good explanation of ported vs manifold vacuum, so that anyone else coming along later that reads this may find it useful. Basically, always use manifold vacuum when possible since the idle mixture is generally lean on most carbs (and due to overlap/cylinder dilution) compared to high engine loads and acceleration, and lean mixtures need more spark advance. (one exception could be having a cam installed that results in fluctuating idle vacuum).

http://chevellestuff.net/tech/articles/vacuum/port_or_manifold.htm

372 posts

·

Joined 2009

I have the same cam, and I get about 9 inches of vacuum at idle (800rpm in drive). I have the 4.5 power valve, 72 front and 76 rear jets in my 750 with the secondaries butterfly open one full turn of the set screw underneath. Timing is set to 16 initial with mechanical at 20 so 36 total and it's all in my 3000 rpms ( i have a timing tape on the stock balencer so it may not be super accurate). I run the vacuum advance off the intake, I did have to back off the set screw inside limiting the amount due to slight load pinging. I am using Champion rc12yc plugs. I know the cam is a bit much but we are getting very different results with a very similar engine. I have forged flat top TRW pistons, stock rods and crank. The heads are 75cc. Should be around 10.5:1 CR. I run 93 octane pump gas. I haven't checked compression in a while (very hard to do all the cylinders in the car with the shock towers), but I would follow the recommendation to check compression. If you have a couple burnt valves it could cause the symptoms you are describing.

2,673 posts

·

Joined 2006

If I am reading this correctly, you have a big cam in a 429. You are trying to get it to idle below 1000 rpm. Why? There is nothing wrong having it idle 1000-1200 rpm with a big cam. If you want it to idle at 700 rpm, put in a smaller cam.

Just because someone else can get their engine to idle lower or smoother does not mean you can do the same with your combination of parts.

Dave

Just because someone else can get their engine to idle lower or smoother does not mean you can do the same with your combination of parts.

Dave

7 posts

·

Joined 2016

When my stock 460 had a high idle issue of around 1100 to 1300 rpm at idle, I tried several different fixes to no avail. What finally fixed it was replacing the ported vacuum switch-Standard Motor Products PVS26- I bought off amazon, or can be found on rock auto.

10 posts

·

Joined 2016

I had a thumpr cam in my 460 and removed it for the very same reasons you experience.

I loved the idle sound, but did not want to drill out the butterflies on the carb.

Also the cam made it run like a switch. doggy until 2500 then the switched flipped and ran like a bat out of hell.

I loved the idle sound, but did not want to drill out the butterflies on the carb.

Also the cam made it run like a switch. doggy until 2500 then the switched flipped and ran like a bat out of hell.

Dads70cobra

Discussion starter

23 posts

·

Joined 2016

After visiting with Tara-fied (Craig), he gave me a whole new reason to look into this some more. I dug into it some more, went back and double checked my recent carb rebuild, and found that i mistakenly used the incorrect base to body gasket. Four holes were not being utilized (assuming something to do with the idle circuit). Installed correct gasket, save Walla. It idles! I've got a little more timing issues to iron out, but i am finally headed in the right direction. Thank you to all that gave ideas and input!

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 682K

- members

- 40K

- Since

- 2006

A forum community dedicated to Ford big block owners and enthusiasts. Come join the discussion about performance, modifications, horsepower, tuning, build specifications, and more!

Explore Our Forums

Top Contributors this Month

View All

PSIG

59 Replies

429GALAXIE

42 Replies

ryanandhisf250

31 Replies