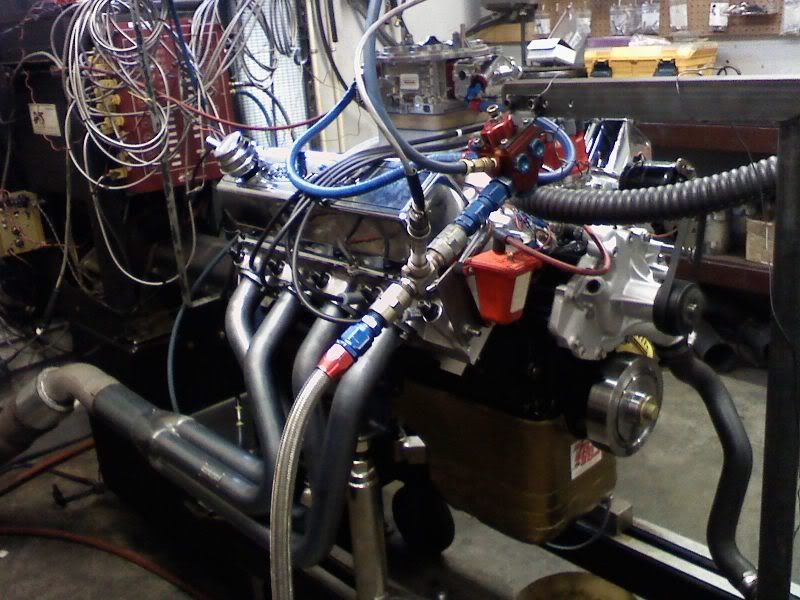

Here is my BF Evans / Jet Boat Bob built 572 pump gas street engine... to be installed in my 1970 Torino GT

A460 Block (4.5 bore)

Scat Forged crank (4.5 stroke)

Scat Forged H-Beams

Diamond Forged dish pistons (10.6:1)

P-51 out of the box (Ti retainers, standard P51 valves)

Full solid roller, custom grind roller cam, FRPP roller rockers

Jomar stud girdle

MSD 351w distributor w/ bronze 460 gear.

FRPP alum. water pump

FRPP t. chain set .

Kaase oil pump

FRPP A521 damper

ARP head sud kit

FRPP victor style intake

QFT 1050 Dominator

Jomar power cone spacer

![Image]()

![Image]()

A huge thanks to Lem Evans for his *exceptional* customer service (and hospitality). I sent an email to Lem asking about building an engine for me. I got a CALL back within an hour! Lem took the time to talk to me about my goals, worked out some of my questions on unknowns... came back to me in a few days time with a price quote... and after a few changes, ADDITIONS and modifications came within dollars of his original quote... NO hidden suprises.

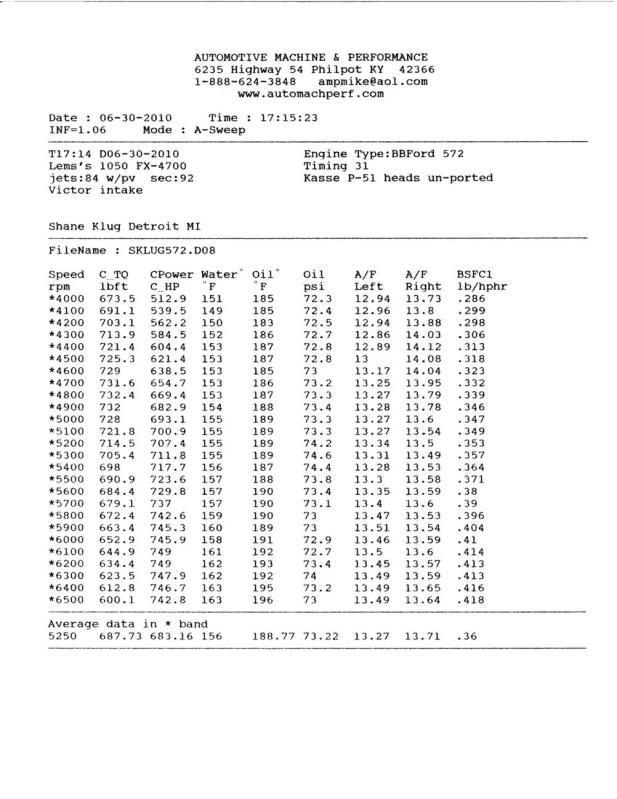

Big thanks for a job well done to Jet Boat Bob, super nice guy beautifull job on the build!... and Mike from Automotive Machine & Perf for the dyno session and help packing the big block for the long rige home!

Shane

A460 Block (4.5 bore)

Scat Forged crank (4.5 stroke)

Scat Forged H-Beams

Diamond Forged dish pistons (10.6:1)

P-51 out of the box (Ti retainers, standard P51 valves)

Full solid roller, custom grind roller cam, FRPP roller rockers

Jomar stud girdle

MSD 351w distributor w/ bronze 460 gear.

FRPP alum. water pump

FRPP t. chain set .

Kaase oil pump

FRPP A521 damper

ARP head sud kit

FRPP victor style intake

QFT 1050 Dominator

Jomar power cone spacer

A huge thanks to Lem Evans for his *exceptional* customer service (and hospitality). I sent an email to Lem asking about building an engine for me. I got a CALL back within an hour! Lem took the time to talk to me about my goals, worked out some of my questions on unknowns... came back to me in a few days time with a price quote... and after a few changes, ADDITIONS and modifications came within dollars of his original quote... NO hidden suprises.

Big thanks for a job well done to Jet Boat Bob, super nice guy beautifull job on the build!... and Mike from Automotive Machine & Perf for the dyno session and help packing the big block for the long rige home!

Shane